HOME > Production System >Production Form of Gear Processing & Automated production line

Production Form of Gear Processing

- ・We utilize processing and measuring jigs, and gear grinding tools in-house designed and manufactured.

- ・We save labor by promoting automation. (any maintenance including jigs and programing is developed in-house support.)

- ・We achieve tooling cost reduction by; reproduced polishing of tools for gear, improvement of using tools longer life by hard coating layer processing business, or inexpensive stocking through import and sale business by Kikuta Giken Co., Ltd..

- ・We achieved significant reduction in tank cleaning by sludge less of cutting and grinding fluid, and cost reduction by prolonging of the coolant fluid with Cyclone Filter Apparatus of Kikuta Giken Co., Ltd..

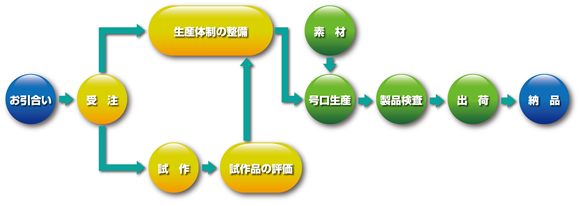

Contract production flowchart

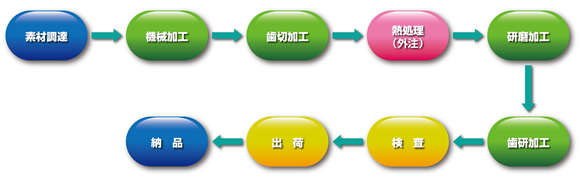

Production flowchart within the company

Automated production line

We succeeded, by promoting automation (robotic), the cost reduction due to labor saving and the elimination of products scratches and dents that occur when the intervening hand of the worker in the process. In addition, we improve the quality realizing the flow of products "from box to box”, that is, eliminating the hand of man as much as possible.

Part of automated production system of gears for automotive engine which is developed in-house.

Part of automated production system of gears for automotive engine which is developed in-house.

|

|

|

|

|

|

||||